plastic parts

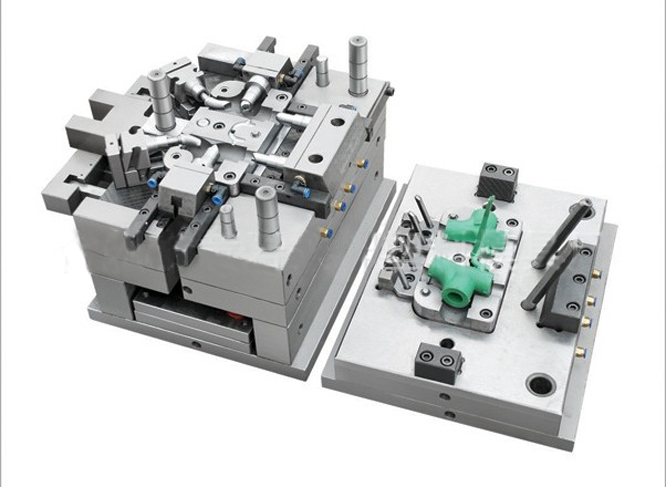

Why "real" samples?

For consumer products it is often sufficient to get first samples from 3D printing.

For industrial products this is rarely enough.

In order to validate a product, the structure and material must be the same as in the final product.

Only injection moulding can do this.

In some cases there is a compromise possible, at least for first samples:

machining the parts from a solid block of the target material.

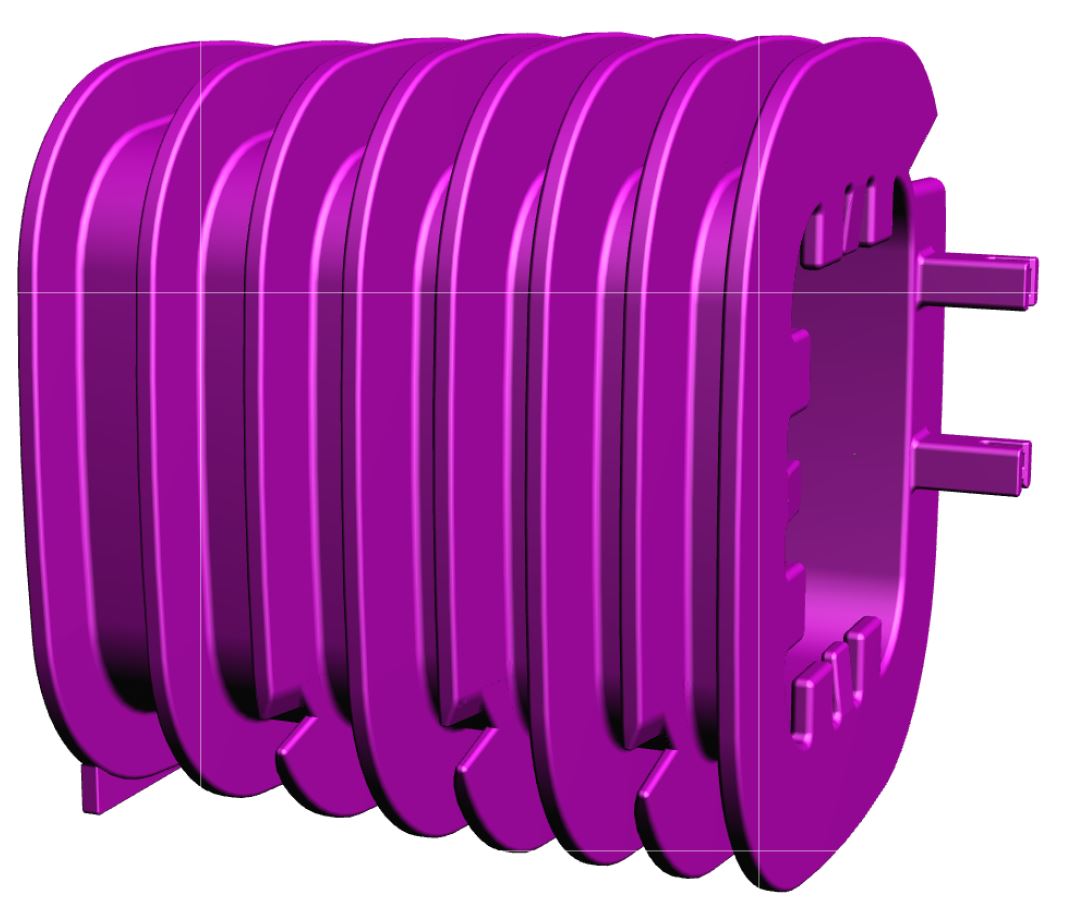

injection moulding

To make a mould for injection we need the following customer input:

1. plastic-material: we can use any kind of plastic, including silicone and glass-filled plastic

2. specifications for the surface of the parts; rough, polished or pickled to certain spec.

3. a 3D model (.stp file) If this is not available we will make it based on the customer's input.

4. a 2D drawing with tolerances

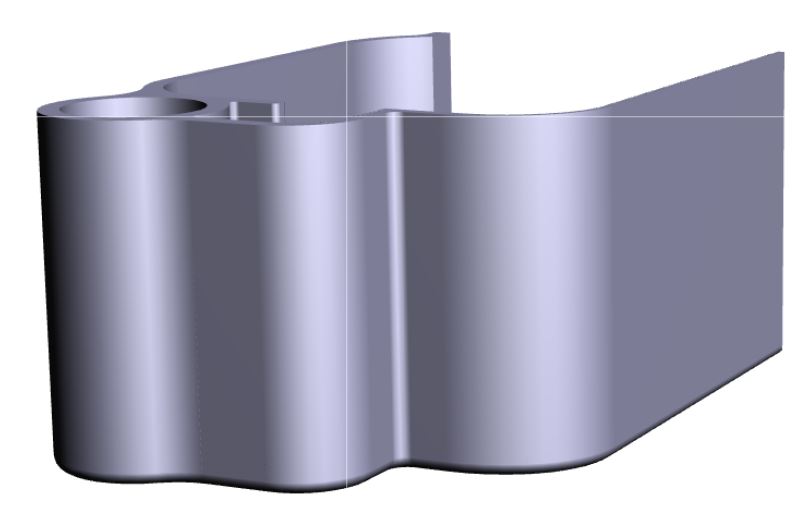

CNC machining

If samples are required really fast; not just for "look and feel" but for some initial testing,

machining a few pieces from a block of the targeted material can be a solution.

This technique would also allow to make the same part using several different plastic materials to find

the best solution which can then be further developed by making an injection mould for this part.

To produce samples by machining we need the following customer input:

1. plastic-material: we can use any kind of plastic, except soft plastic like silicone

2. a 3D model (.stp file) If this is not available we will make it based on the customer's input.

3. a 2D drawing with tolerances